Small world, performing big solutions

SCIL combines the resolution and accuracy of rigid stamps with the flexibility of soft stamp methods. SCIL takes away all the drawbacks of rigid lithography, achieving nanometer resolution without the pattern deformation that other soft stamp methods suffer from.

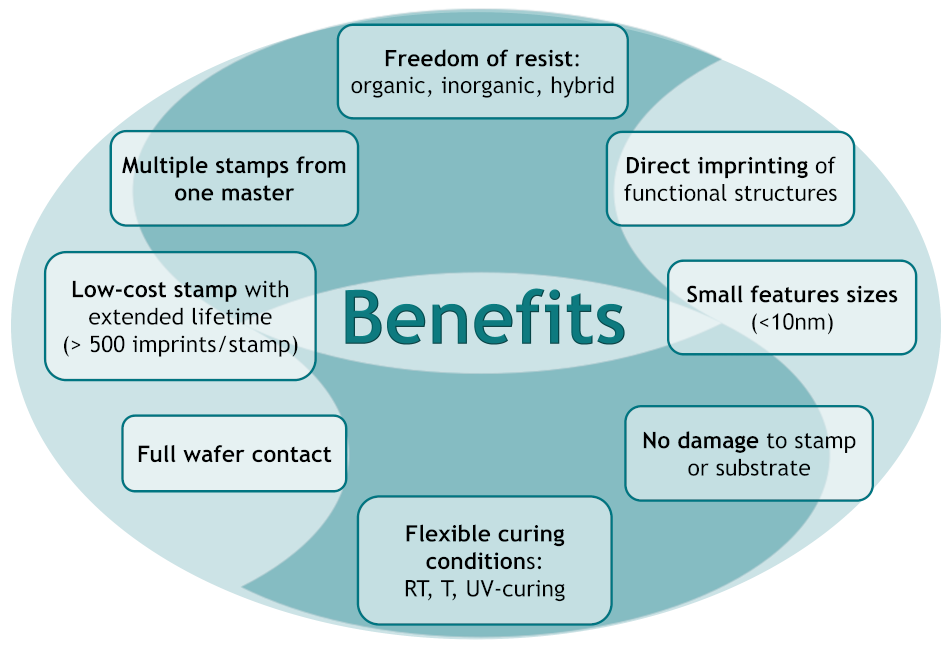

SCIL Nanoimprint solutions benefits

Discover the full range of products SCIL Nanoimprint solutions has to offer to obtain high quality nanoimprints.